Before procuring parts and materials from abroad, we visit suppliers to see their facilities and exchange information not only on Japanese sizes and specifications but also easier-to-use development and test methods.

Before procuring parts and materials from abroad, we visit suppliers to see their facilities and exchange information not only on Japanese sizes and specifications but also easier-to-use development and test methods.

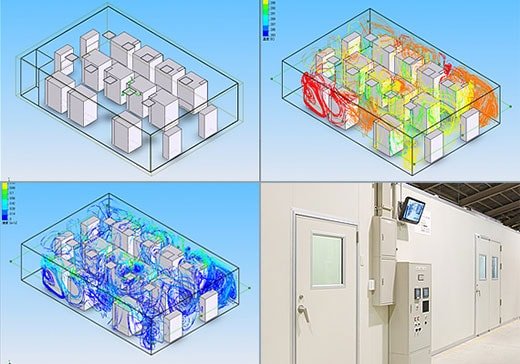

At Miwa, we simulate the airflows inside of glove-boxes and larger scale projects by 3D modeling. The system we use can also be paired with high-speed cameras to make double-checks under empirical conditions. And, more recently, we have used it in design work for highly airtight, low CO₂ rooms to simulate internal pressures and temperatures in addition to airflows.

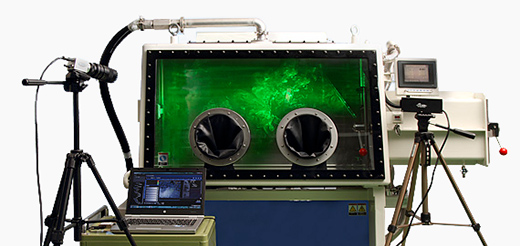

This unit serves for pinpointing the best encapsulation conditions. The technologies that went into building our encapsulation test line for organic EL production have been applied to it. Though the unit is compact, it can be expanded into a larger system by connecting optional units to the flanges. Moreover, improvements have been made to the method used to immobilize the cell panels so that panels can be encapsulated in a wide pressure range in a short amount of time.

This analyzer can connect with the detachable heater of a gas chromatograph to measure impurities that attach to absorbents and areas inside the chamber.

This device simulates the unknown airflows of closed systems by visualizing the airflows inside the chamber and capturing them with a high-speed camera.

We produced a vacuum drying furnace for de-gas of a glove box and Parts in own company. By introduction of this facility, We just introduce a glove box and do vacuum drying, and gas elimination and the nonconductor membrane formation from stainless steel materials becomes possible. We increase aiming at the quality and the performance improvement of a device more in future.

I reduce particle in a minimum by doing glove box assembling in a clean room and increase aiming at the quality / the performance improvement.

The ultra-pure water produced be this unit can be used to wash equipment and products for use in clean environments.

Specific resistance … 17.5 MΩ・cm or more

Particles … 30 per ml or less

Viable bacteria … 0.5 per ml or less

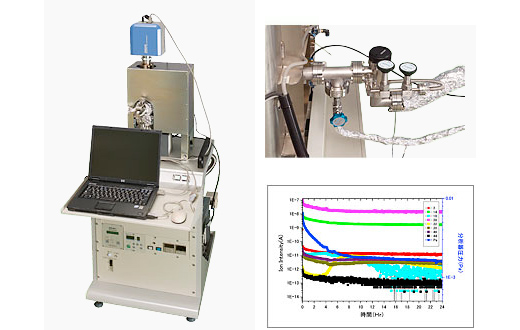

Gas analysis by a ppb level became possible with APIMS(Atmospheric Pressure Ionization Mass Spectrometer) and gets possible to detect the ppb domain where the measurement was impossible in a dew point recorder precisely early.

This analyzer can be used to analyze a wide range of gases, e.g., residual gases under vacuum, process gases, thermal desorption gases, etc.

I do glass Encapsulation System with FPD / TFT / Solar-battery with a purpose with life EL (Encapsulation System) and will establish technology as the total maker which included a process instead of device maker named .

This vacuum meter can measure quantitatively high pressures in the range of 10⁻² to 10⁻¹¹ Pa.

By switching the three frequencies (28 kHz, 45 kHz, 100 kHz) at high speed, it is possible to perform strong washing on the member without unevenness by moving the standing wave.